Frozen goods

For the frozen food sector, we have designed machines with special features to optimize productivity in low temperature environments.

-

Various diced vegetables, peas, green beans, grilled vegetables, soup mix etc.

Various diced vegetables, peas, green beans, grilled vegetables, soup mix etc.

-

Ready meals, pasta, cheese etc.

Ready meals, pasta, cheese etc.

-

French fries etc.

French fries etc.

-

Diced bacon, meatballs, cutlets and chicken legs etc.

Diced bacon, meatballs, cutlets and chicken legs etc.

Ecopackaging: the future

of packaging

The energy efficiency of the machine is guaranteed by the construction according to the EU regulation 2019/1781, through motors connected to inverters, in accordance with IEC 60034-30 standard on the efficiency classes of AC motors with mains power supply.

Paper film

Compostable materials

100% recyclable

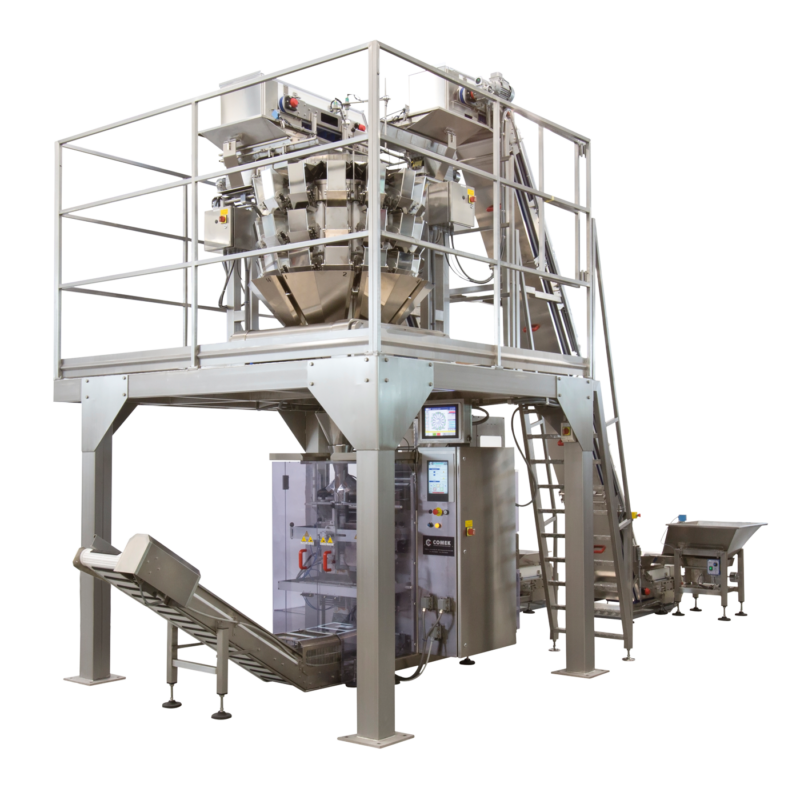

Weighers

M version.

DP version.

DP-2 version.

The components in contact with the products are made of AISI 304 or AISI 316 stainless steel with plain or rigidized sheets to improve product flow.

Automatic distribution systems to interface the weighers with thermosealing or thermoforming machines, HFFS machines for pouch bags, special filling lines.

Self-calibration of weighing buckets to offset the ice layer that forms during processing. Doors with special shapes prevent the escape of small products.

Software for controlling the permanence of the product in the weigher to ensure the maintenance of freezing temperatures during the weighing and packaging process.

Vertical packaging machines

PACKAGING MACHINE OMNYA EVO

Triple mode of operation: continuous, intermittent and Doypack.

Realization of pillow bags, block bottom bags, block bottom with four seals, doy-pack.

PACKAGING MACHINE VPB EVO

Mode of operation: intermittent.

Realization of pillow bags, block bottom bags, block bottom with four seals.

Mode of operation: intermittent.

Realization of pillow bags, block bottom bags.

SPECIAL DEVICES

Anti-obstruction systems entering the forming tube and settling the product in the package prevent production stops.

PULSE WELDING SYSTEM

With quick change of wear parts, special hot bar welding systems controlled by brushless servo motor, suitable for heat-sealable difficult packaging materials.

Horizontal packaging machine

AISI 304 stainless steel cantilevered frame for maximum hygiene and ease of cleaning.

LD horizontal sealing group to ensure hermetic packaging.

Denester trays from 1 to 4 rows with quick and easy format change.